Introduction

Wire stripping is a fundamental process in a wide range of fields—from electrical work and manufacturing to automotive repair and recycling. Stripping away the insulation on wires allows easy access to conductive metal, whether it’s for making secure connections, testing, or salvaging materials. While some may be familiar with the manual methods of wire stripping, investing in a specialized wire stripping machine can vastly improve productivity, safety, and output.

Understanding Wire Stripping Basics

Before diving into the specifics of wire stripping machines, it’s helpful to understand what wire stripping entails. Wire stripping involves the removal of the protective insulation on a wire to expose the conductive metal beneath, allowing for connectivity or recycling.

- Types of Wire: The two most common wire types are solid and stranded. Solid wires are a single metal core surrounded by insulation, while stranded wires consist of many small strands twisted together, making them more flexible.

- Wire Gauge: Wire gauge refers to the thickness of the wire, with lower numbers indicating thicker wires. It’s essential to choose a wire stripping tool that can handle the gauge of wire you’re working with to avoid damaging the wire itself.

Challenges with Traditional Wire Stripping Methods

Many people start with manual methods for wire stripping, using basic tools like pliers or knives. However, these methods come with significant downsides:

- Inefficiency: Manually stripping wire is labor-intensive and time-consuming, especially for larger projects or recycling operations.

- Inaccuracy: It’s easy to accidentally nick or cut the wire itself, which can compromise electrical integrity or reduce material value in recycling.

- Safety Risks: Manual methods require close handling of sharp tools, increasing the risk of injury.

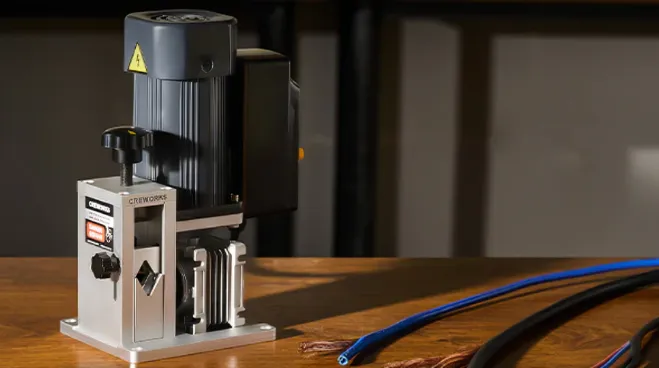

This is where the Creworks wire stripping machines come in, providing a faster, safer, and more effective way to strip wires accurately.

Benefits of Using Creworks Wire Stripping Machines

Choosing a wire stripping machine over traditional tools can elevate your wire stripping efficiency significantly. Here’s how:

- Time and Labor Efficiency: Creworks machines, whether manual or automatic, streamline the wire stripping process, saving time and effort on every project. Their high-speed capability is ideal for professionals who handle large volumes of wire regularly.

- Cost-Effectiveness: Recycling stripped wire turns waste into valuable materials. By investing in a wire stripping machine, you can quickly recover the cost by selling the stripped metals, particularly valuable copper and aluminum.

- Durability and Reliability: Built with high-grade materials like durable alloy steel, Creworks machines are engineered for longevity. They are designed to withstand rigorous use, making them a dependable choice for heavy-duty or frequent wire stripping tasks.

Types of Creworks Wire Stripping Machines

Creworks offers a variety of wire stripping machines to suit different needs and applications. The following are two common types:

- Manual Machines: Ideal for DIY enthusiasts or occasional use, manual machines are user-friendly and require no power source. They provide great control, making them ideal for smaller projects.

- Automatic Machines: For larger jobs or industrial environments, automatic wire stripping machines are unmatched in speed and consistency. These machines can handle a wide range of wire sizes and types, reducing the time needed for each wire.

Key Features to Consider When Choosing a Wire Stripping Machine

When selecting a wire stripper machine, there are several features to look for, each of which can impact the machine’s usability and versatility:

- Motor Power: Higher motor power allows the machine to strip thicker wires and operate at a faster speed, increasing productivity.

- Wire Size Range: Look for a machine that can accommodate a variety of wire sizes. Creworks machines are designed with versatility in mind, handling multiple wire gauges from thin cables to thicker, insulated wires.

- Ease of Use: Simple, intuitive controls are important, especially for beginners. Creworks machines are designed for user-friendly operation.

- Safety Features: Safety is a priority in wire stripping. Creworks machines come with safety guards and protective designs that minimize risks during operation.

Conclusion

Wire stripping doesn’t have to be a painstaking, risky process. With Creworks Wire Stripping Machines, you’re investing in a solution that boosts productivity, maintains quality, and improves safety. Whether you’re stripping wire for industrial applications, recycling, or personal projects, Creworks offers a range of machines designed to meet your needs effectively. Explore Creworks’ range of wire stripping machines today to find the right fit for your projects and experience the difference in efficiency, safety, and quality.